What Exactly Is The PVC-Coated Polyester Yarn Coating Machine?

What is a PVC-Coated Polyester Yarn Coating Machine? How Does It Work?

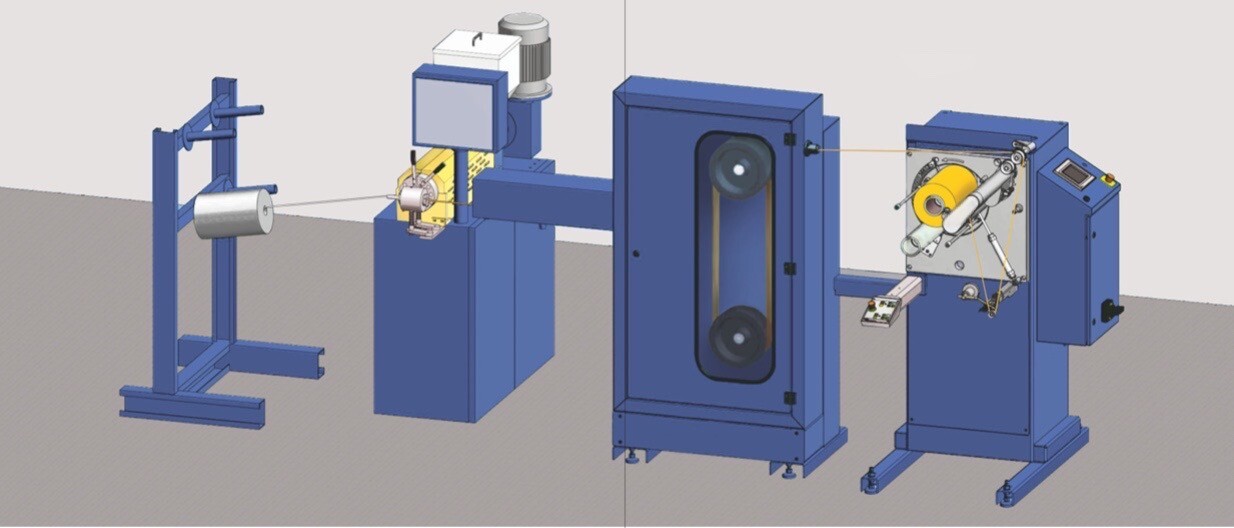

This is a high-performance machine designed to coat 100% polyester yarn or fabric with PVC. The production process includes yarn unwinding, extrusion coating, cooling and shaping, and automatic winding, enabling efficient and continuous production suitable for various industrial applications.

Why Is This Material Gaining Popularity in Industrial Applications?

PVC-coated polyester is a composite material that uniformly bonds polyvinyl chloride (PVC) to 100% polyester fibers. It combines the high strength, flexibility, and toughness of polyester yarn with the added benefits of PVC coating, such as waterproofing, UV resistance, flame retardancy, and anti-static properties.

What Key Technologies Are Integrated into the Equipment?

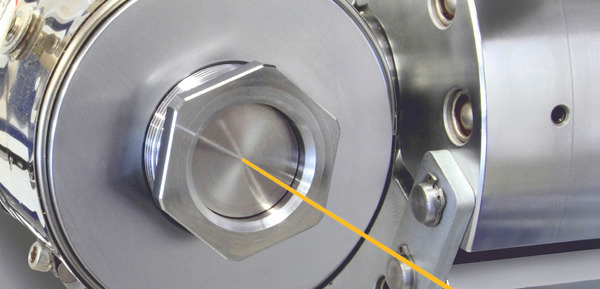

The machine is equipped with a screw extruder featuring multi-zone temperature control, allowing for precise PVC melting. The extruded material is bonded with the polyester core yarn at the die head, followed by a water bath and multiple roller cooling zones for relaxation. Tension throughout the line is precisely controlled using frequency inverters and spring brakes, ensuring stability and efficiency during the coating process.

What Are the Advantages of the Final Coated Material?

PVC-coated polyester offers a combination of strength and durability with the following benefits:

Fully waterproof for use in humid or outdoor environments

Excellent tear resistance and abrasion durability for longer service life

Complies with international flame-retardant standards for enhanced safety

Anti-static and UV-resistant properties make it suitable for long-term outdoor use

Smooth surface for easy cleaning and maintenance

What Is the Key to Extrusion Coating? Multi-Zone Temperature Makes Control PVC "Obedient."

How Is High Performance Ensured After Coating? Cooling and Shaping Are Critical for Quality

After coating, the material is processed by Rainbow’s advanced cooling system to eliminate residual stress. It first passes through a 4.4-meter water bath, then through multiple guide rollers in the cooling unit. Yarn tension is precisely controlled by frequency inverters. This cooling and stretching process enhances dimensional stability and mechanical performance, ensuring the coated material has excellent waterproof, abrasion-resistant, tear-resistant, and flame-retardant properties.

Is the Operation of the PVC-Coated Polyester Yarn Coating Machine Convenient?

Rainbow Intelligent Equipment’s PVC-coated polyester yarn coating machine is designed for user-friendliness and simplicity. Operators can easily configure and adjust settings to meet diverse production needs, significantly reducing operational complexity and maintenance costs.

With its accumulated experience in extrusion coating technology and engineering applications,Rainbow Intelligent Equipment continuously upgrades its production lines and mature technical solutions to meet the growing market demand for high-performance materials. It provides customers with a one-stop solution from material selection to finished product manufacturing. PVC-coated polyester yarns are being adopted by more and more industries. In the future, Rainbow will continue to explore more environmentally friendly and intelligent material processing methods to inject new vitality into the composite material manufacturing industry.

Request A Quote