Board width:915mm/1220mm/1830mm/2050mm

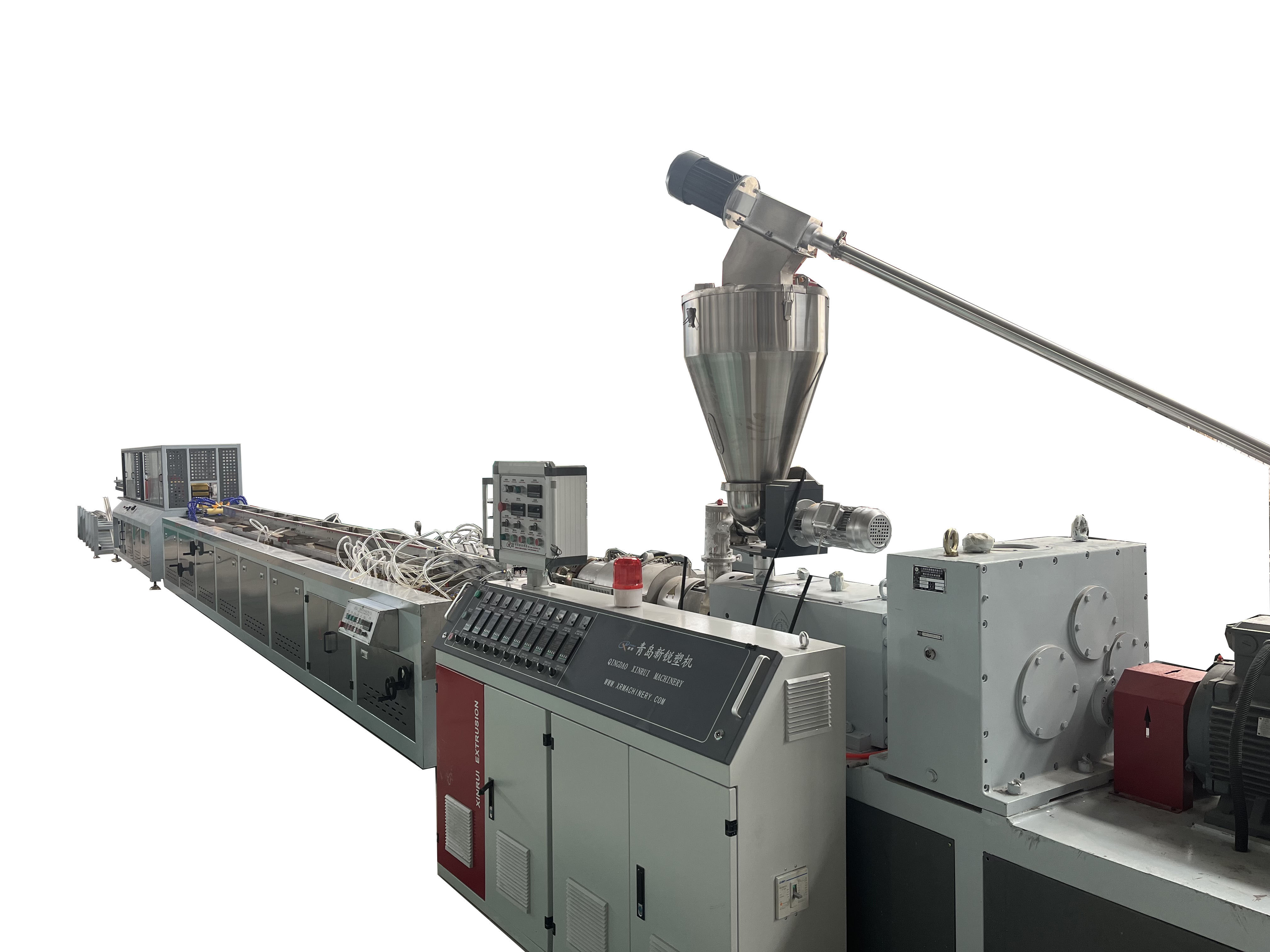

PVC Foam Board Making Machine

Brief Introduction:

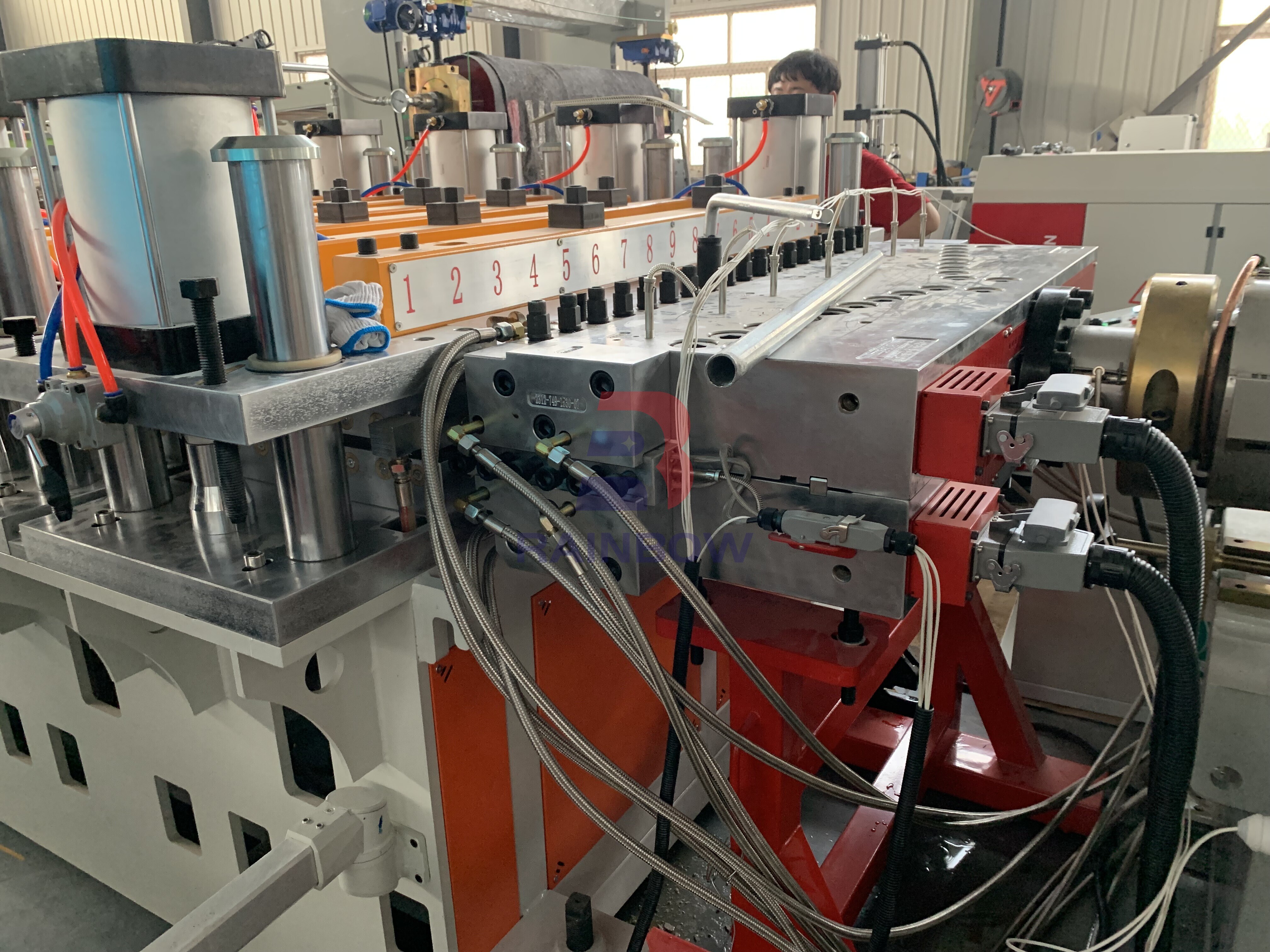

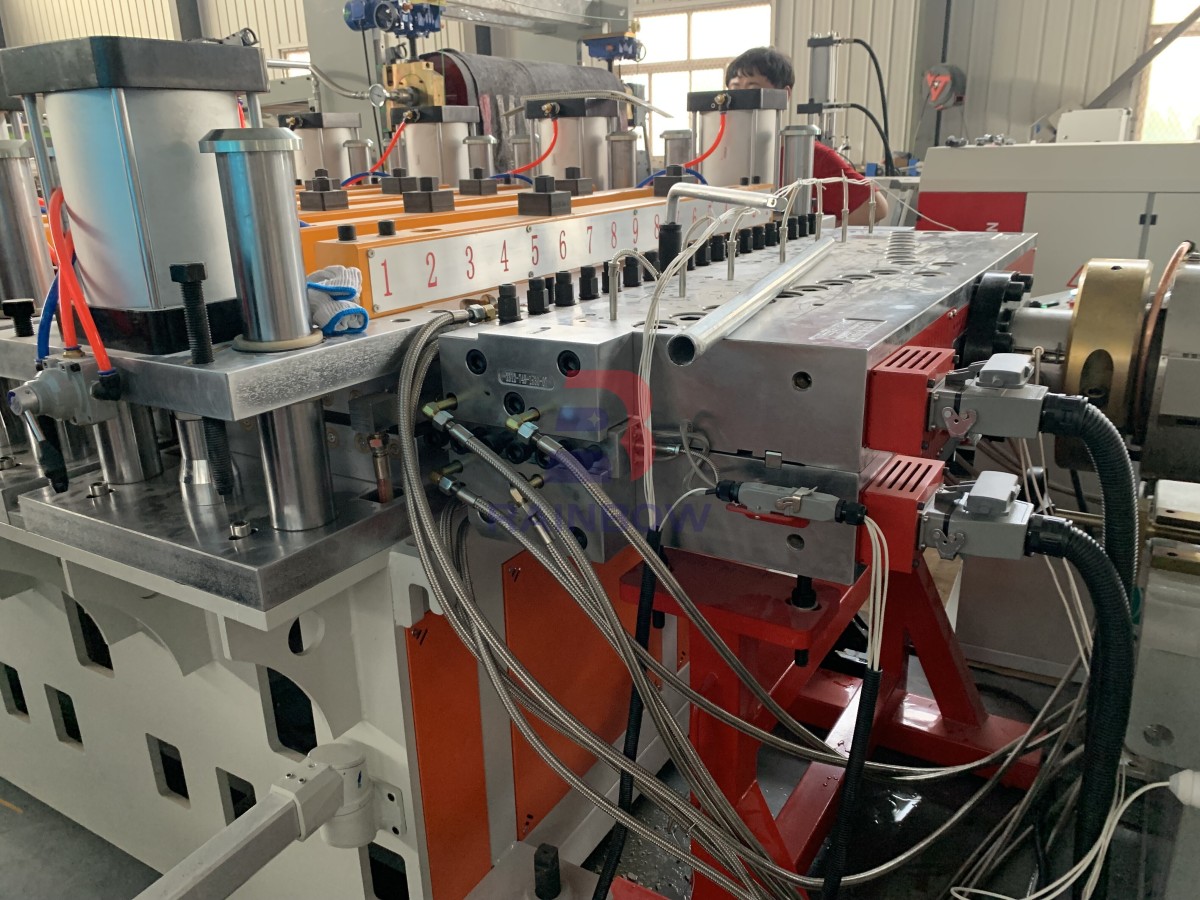

1.Extruder adopts bimetal screw and barrel of high abrasion resistance and corrosion resistance that could largely increase lifetime of screw and barrel.

2.Extrusion die adopts P20 material which is of higher strength,longer service time and easier operation than traditional die material.

3.Calibration cooling platform is with superior cooling effect which could improve the crust quality.

4.Board surface treatment could be laminated,heat transferred,printed and UV coated.

5.This production line is equipped with all requested auxiliary machines as mixer,pulverizer,crusher,chiller,mould temperature controller,dust collector and so on.

6.High quality electrical components and optimized electric design could ensure stable production and low maintenance.

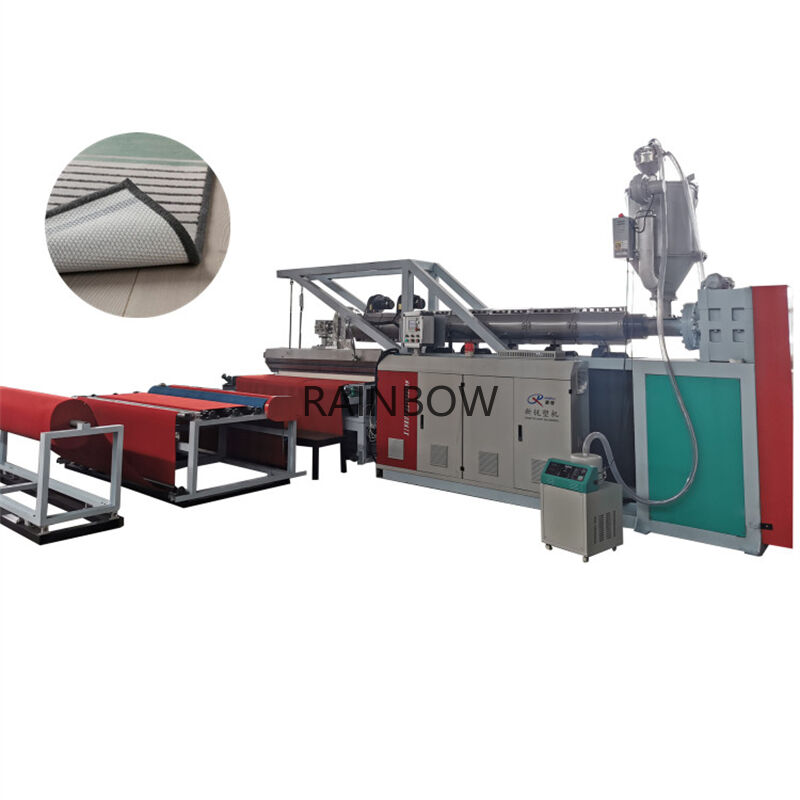

This production line could produce furniture board,doorboard,advertising board and building template by adjust formulation.

PVC Foam Board Making Machine Size:

Board thickness:3-40mm

Board width:915mm/1220mm/1830mm/2050mm

PVC Foam Board Making Machine Features:

1.Even plastication and agglomeration

2.Reliable quality

3.Long servicing life and direct conversion of powder into plastic products.

PVC Foam Board Making Machine Application:

Advertisement: Such as screen printing, computer lettering, ad board.

Architeture: Such as buliding wall board, decoration board, housing, office, public buliding interlayer, commercial decoration shelf, non-dust room board, ceiling plate.

Transportation: Such as steamship, aeroplane, carriage, traine compartment, roof shed, case core layer, inner upholster.

Industry: Such as chemical industry antisepticizing project, thermoforming , for refrigeratory, for temperature keeping, for environment protection.

Request A Quote